Greetings!

Welcome to Scifi-Meshes.com! Click one of these buttons to join in on the fun.

Quick Links

ModelingStar Trek ship Modeling Question

Hey all, ChiefBrex here,

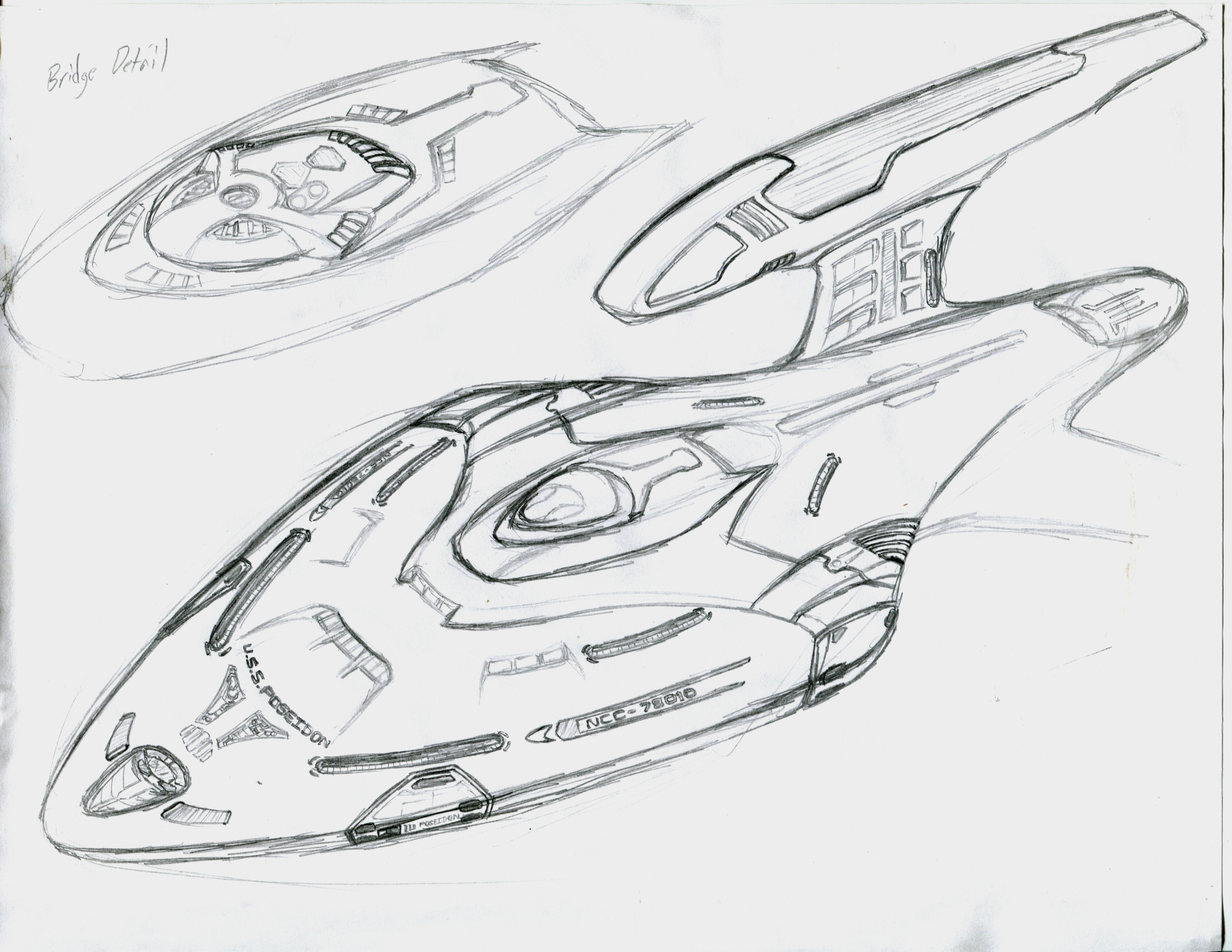

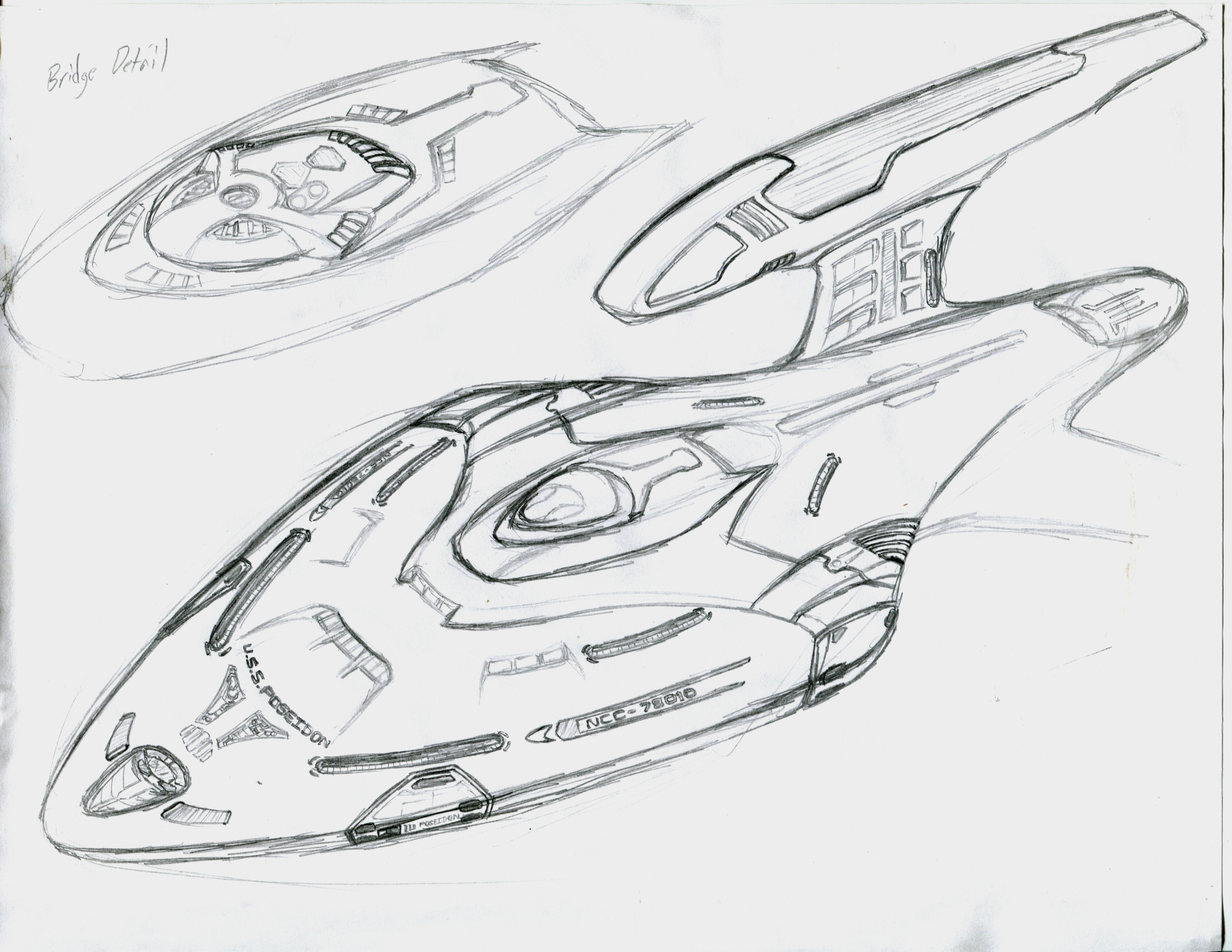

I'm working on a star trek starship design that a friend and I co-created. In the past I've done work on TOS ships, and have wanted to do TNG era ships, but have always struggled with the curved designs. On this design of mine, I'm trying to work out the bridge module and deck 2. I have tried using a sphere, tried using a sphere and a cylinder. But, no matter what, I get to a point where I'm literally confusing myself on what step to take. I'm working with Max2020. I've attached a picture of my current progress (I'll include the ship model, the sketches, and my current bridge module progress). Hopefully someone here can be of help?

The Bridge Detail is what I'm trying to model right now:

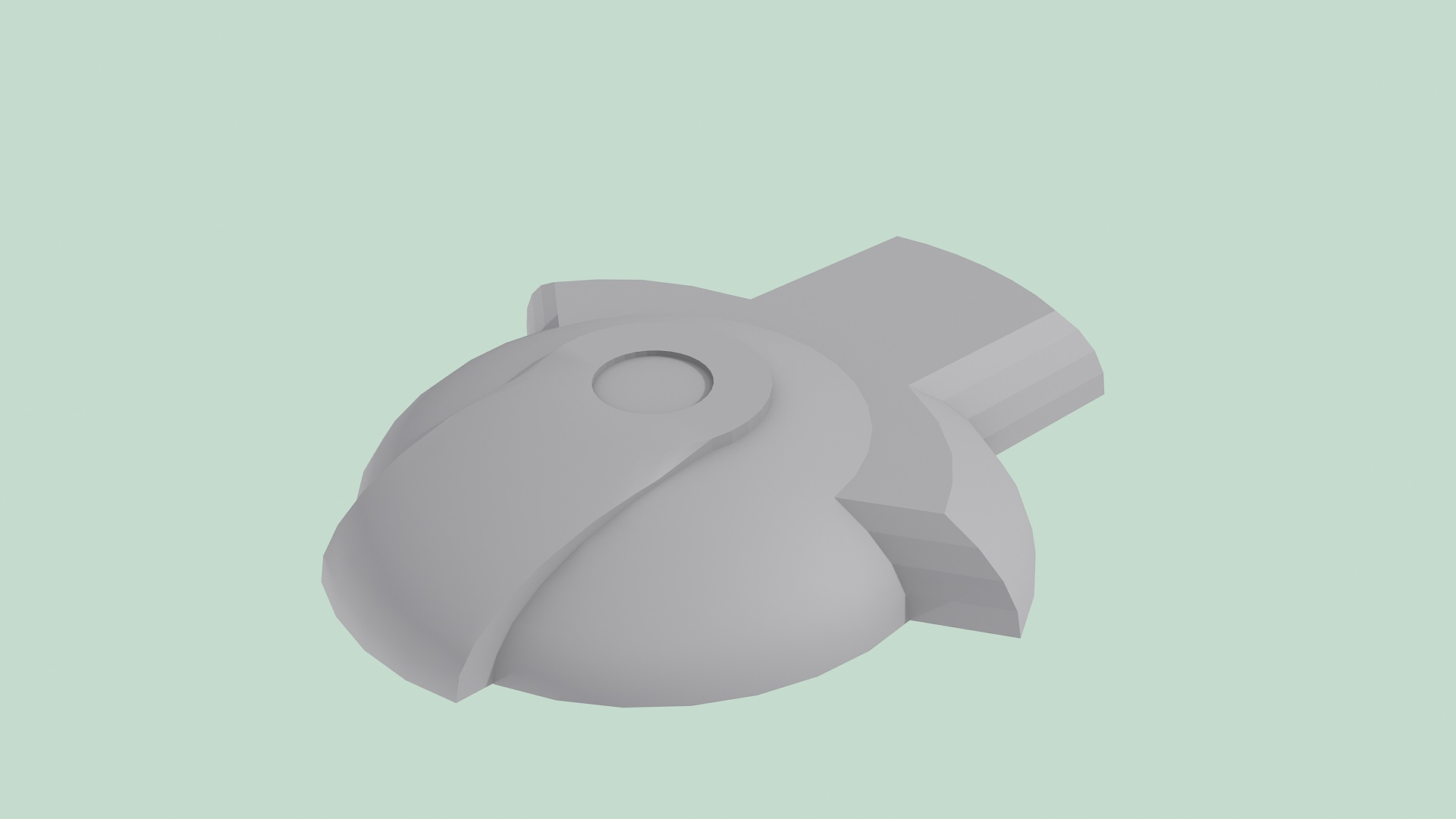

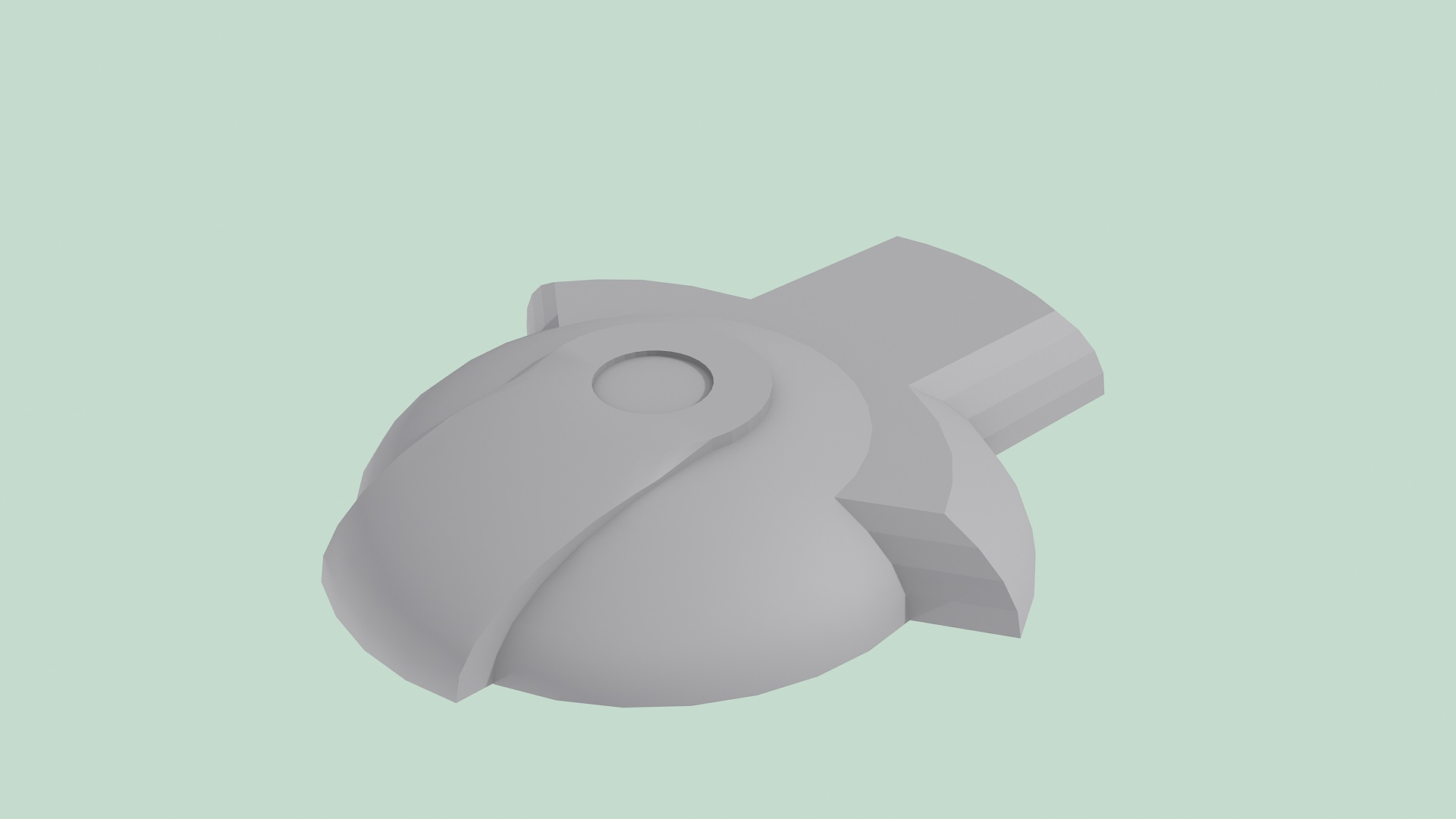

This is the bridge module as I currently have it:

I'm working on a star trek starship design that a friend and I co-created. In the past I've done work on TOS ships, and have wanted to do TNG era ships, but have always struggled with the curved designs. On this design of mine, I'm trying to work out the bridge module and deck 2. I have tried using a sphere, tried using a sphere and a cylinder. But, no matter what, I get to a point where I'm literally confusing myself on what step to take. I'm working with Max2020. I've attached a picture of my current progress (I'll include the ship model, the sketches, and my current bridge module progress). Hopefully someone here can be of help?

The Bridge Detail is what I'm trying to model right now:

This is the bridge module as I currently have it:

Additional credits

- Icons from Font-Awesome

- Additional icons by Mickael Bonfill

- Banner background from Toptal Subtle Patterns

© Scifi-Meshes.com 2001-2024

Posts

One thing to be aware of is interior volume and spaces inside. SO think about how those lifeboats are accessed and how the internal halls will lay and what areas are resulting dead spaces.

Sub D (aka turbosmooth or meshsmooth will be your friend for TNG stuff. Suggest looking for tuts on how to manage "smoothing groups" edge loops etc and how sub division affects shapes. It should give you a idea on what to do.

attaching a max2013 file should open in 2020

well apparently site isn't allowing anything but images.

hopefuly this works DB is just a long line of wtf.

https://www.dropbox.com/s/t9ykxp8ihyc2d14/bridge-sample-01.max?dl=0

To be honest, I haven't had much experience using Subdivision surfaces and badly need to experiment with and learn how to use the tool. What I have used so far is a more time-consuming (dumb) method. MadKoiFish is one of the site maestros and again I don't know where you are in your skill set. Forgive me if the following is too rudimentary. As he said it is best to split your design into its component parts.

I start with the basic shapes. In the image below the progression obviously goes from right to left. At the back I made circles and ovals that I borrowed pieces from. I made them, then deleted the polygons I did not want. This includes the flat top and bottom. In certain cases I had to reverse or "Flip" the polygons. This made what was the inside surface of the shape, the outside surface. I moved points and joined them together to make the final crude shape on the left in the back. It might be used as a cutter or stencil pattern on the front image or could be shaped to curve down by cutting IT with the front shape. Most 3D software have tools that let you combine two shapes in a boolean manner. Add, Intersect, Subtract etc.

The front shape was accomplished by making a disk and then pulling the points starting beyond the back half of the disk into the base shape that I wanted. The points I mean are indicated by the raised portion on the right most image in the front. The center front image shows the progression.

Finally I got the raised dome effect by using a tool in my software (Lightwave) called "Bevel." This can be used to add another same shaped polygon above and attached to the first. I then took the points on the top of this second row and used the "size" option and collapsed or pulled in the points to a smaller "diameter." I then selected the smaller diameter polygon framed by these points and pulled a 3rd row with bevel and sized this row smaller too. Keep going until you have as many vertical rows as you like. You can eyeball and create a smooth curve going up. You might have to stretch and move points a little. In this process "symmetry" may be your friend. You can split it down the middle and reproduce the same reversed shape on the right from the shape on the left or vise versa and join them together.

I should add that my "Bevel" can raise a row of polygons above the base shape AND simultaneously make them smaller but I usually run into problems in the sharper corners. By using "Size" I avoid that because size won't make one point cross over the other at a sharper corner.

Hoping this helps and didn't insult your intelligence. I just don't know your experience level.

BTW. Love the engines in your drawing. NICE!

Branden - I've been modeling star trek ships off and on for almost 20 years now. I've only ever really focused on TOS era ships. This ship design that I and my friend developed, is my first TNG era starship. I'm getting used to the interconnected curviness of TNG ships lol.

Thanks for the advice guys! I will definitely give them a try and see what works best for me.

Update: After thoroughly re-reading both your posts, I suddenly feel very stupid! I complete forgot about the bevel option in Max2020. Looking at what you both suggested, I see now that I was making this much more complicated than it needed to be! I will post what I manage to put together and post it here before opening up a WIP of the Poseidon on the forums. Thanks again guys for your help!

turbosmooth and meshsmooth and likely more in newer versions of max are "modifiers" So the process whatever they use is likely hidden by some user friendly name lol. I use turbosmooth cause I just want speed and I only care about Smooth Result/smoothing groups and Isoline Display for viewport speed (KIM you have to turn it off when you go to collapse the mesh as it will leave you with a mess full of verts and few edges) Meshsmooth gives you "classic" "Quad output" and "NURMS" and some more features. Anyhow each software has it's own approach to this. Some even lack the ability to smooth by material ID or smoothing ID. This gives your more options to keep the resulting mesh a bit cleaner and lower poly. Makes things quick to clean up a collapsed subdiv mesh too.

LW has a lot of box modeling cxheats like being able to chamfer things without letting verts cross. Max sadly (least up to 2013) lacks a lot of these tools. Max in 2013 has a defective cutting system too as they altered it since 2010.

Also if you use boolean in max use the pro boolean etc it leaves less vomit to clean. Max is notorious for making mesyy booleans. See my window tut on my blog as an example of how much mess cookiecutter booleans are (LW stenciling)

Anyhow attached are examples of bridges I modeled in parts and welded together and rounded the join area so it looks like a single bit of hull. Often though I will hide joins with a panel line or something as splitting the mesh does help in UVW but in the case of the Bombay I welded it up to make mapping easier (less parts) as I unwrapped that model vs projections.

Here you can see I broke it up into sections using panel grids and other things.

This one even in parts for UVW it was all welded together except a few details into the saucer. Likely never to be seen in most renders though.

If you're going to check out MadKoiFish's thread, I'd suggest having a package of napkins available to keep the drool under control.

Hehehe. I'll keep that in mind!

@MadKoiFish and @Brandenberg Here is the latest attempt of mine, using your advice! I used separate objects, but instead of chamfered boxes and sub division, I used Free Form Deform tool on a cylinder and a sphere. Still feel like the cylinder (the base object) is too short, or the sphere too long. Either way, I can tweak that.

Oh, I also took out smoothing for the moment. I generally save that for the last.

Oh gosh yes. You'll short out your keyboard if you don't. And I'm not even kidding.

I might add, that gaps between ship pieces may actually be preferable. It's closer to reality. Most of us here go to some trouble to make grooves or indentations to give a realistic feel.

The following Greeble is put together as one piece. I went to the trouble so that I could easily select it from my greeble database. I direct your attention to the gap between the valve wheel and the valve housing. I admit that there are tons of other places on this mesh where the same thing should have been done, but it is one example.

Like I said, most monitors use generic drivers anyway. That was just a suggestion if the GPU driver doesn't do the trick.

Go and dl the newest driver for the GPU. Uninstall everything related to video drivers even if it is a default WIN driver. Reboot do not let windows look for a driver (unplug the internet etc) or MS based software and then install the Nvidia driver, KIM they do pack a lot of crap you might not need. Things like 3d viewer drivers and what not. Reboot etc as the install req.

This should fix things MS should not have access to change anything in the software(3ds max) in of itself So unless you messed with say the assigned driver type used in viewports like openGL DirectX Nova fusion or whatever the hell they have now in max (I use 2013 so heh) I suspect ms fucked up your video driver with a crappy one.

If that does not fix it I would look at performance testing software to see if it is cpu gpu etc. Also look for errant running apps that might be eating ram or cpu cycles in the taskmanager.

Then get used to this sort of thing as win10 it is just SOP.

Over the same span of time I've been getting a message about a Windows update but have not allowed it. Something seemed fishy to me. It isn't the usual way Windows notifies me of an update. It looks different. Usual Windows updates go ahead and install when I do a reboot. This one is waiting for permission. Furthermore, there WAS a more normal windows update when I rebooted while this message is still waiting for a response. It just seems odd.

Not that anyone running new hdw has a CHOICE except maybe Linux or some other small OS. Intel DID have a win7 compatible processor but it was not the fastest one out there. Add in win7 is like 95 98se back in the early 2000s, lame horse. >_> Sadly win8 was lame out of the stable, so that was not even a stop gap.

Yeah, with win10 you dunno what is up it already is running your home network like a botnet to supply others with win updates because MS wants to cheap out on it and make users pay through power usage, wear on hdw and use of services not paid for by MS. Add in all the telemetry crap and other backdoor crap in that os. . . .

So yeah could be something got in but I doubt it. It is not like that stupid messaging system on XP and win7 that allowed exploiters to sent you notifications in a system window. Some major stupidity on that one. But then again win10 so who knows what more stupidity ms has in store for users.

As for asking vs implementing on reboot. In the past there was a HUGE push to avoid rebooting to allow updates issue is as time went on the os was assigned to lock files in use or recently in use to avoid virus from altering those while the system is running. So you always had the mixed updates in win7 and 8. So it slowly became the MO to have updates apply aftyer a reboot. Eithercase there could be a few randoms which wont require this. Verify the update number what it is for and what not and google it up. It could be something as stupid as a driver update for something you do not need. If you cannot find any info on exactly what updates it is applying google the wording in the diologe and how the window appears and you might find more info on it. And let you conclude what it is.

ANYHOW I hope the driver refresh did the trick for Brex. It is the only thing I can think of that would cause max to slow down. Least with the discription of having to mess with the os due to a bad update. It could easily been a coincidence thing and he has something HDW related going bad. Doubtful but, Shrug.

UPDATE: So, yeah, no idea what the "update" did, but all of the nVidia software and updaters are saying that my graphics card is not a compatible piece of hardware....

I am not sure what to do at this point. Definitely know I'm not playing games and such until I get this fixed.

In fact, I just did a search and the GTX 1660 TI is indeed covered by driver 436.02, which was just released last week.

Ok just did a google on that card. . . . . . take what you will from it post is 5mo old with even recent posts on the subject.

https://www.nvidia.com/en-us/geforce/forums/discover/296238/gtx-1660-ti-and-windows-10-compatibility/

It is hard to say without having the box in front of me to beat the head against. I suggest at this point you google the issues and look at what situations match yours. I have seen the nvidia installer have a fit when some of the plug and play options are disabled in the "bios" UEFI.

Short of wiping the system the only option is to take various steps one at a time 1 attempt to let win install a driver then update that, change cards, try various versions of nvidia installers working backwards. ETC. Heck even try re-seating the card. Hell, try reseating everything in the system ram, add on cards, gpu, etc short of the cpu.

Also check device manager and look for anything with a yellow exclamation mark on it.

Dunno what hdw you have access to for me Id pull the hdds and swap in a junker and reinstall to rule out any hdw issues.

Keep in mind any other possible changes made in the time period of the update new hdw new usb devices relocation of connectors etc.

So much so they become a security risk to a home network. EXP with a bone stock chrome and IE. Hell chrome in of itself is malware.

Another reason to vet updates is MS is known to push spyware as critical security updates. Shit tonne of telemetry crap hits all flavors of WINDOWS now. Started with win10 having it out of the box when MS found people avoided the update more than expected they rolled that shit out to win8 then win7 and I have heard a few mention it was on XP systems too. Reason to not use cumulative updates either. As they will roll all sorts of crap into those.

Kinda funny at one time updating was actually useful, now if anything it causes more harm. Does not matter the OS. Hell I have gotten to the point I do not update android apps anymore as they just add more spam malware crap or access to permissions the app has no business having. Often the updates just break more things than fixing.

In general though MS it is best to never install anything not a critical update. Updating the stupid win-defender eh ok certs ok but if it is drivers or other bullshit do not bother. MS accepted updates are often 2yrs old. It is liek laptops with video cards in they are fixed so you cannot install a raw driver set from the gpu manufacturer you have to wait fdor the laptops manufacturer to OK a driver. ASUS is one of the bad ones for this. Get stuck with 3 and 4 yr old bug infested drivers. Defies the whole point of PC where you have control of what you do and what you run.

That could be something to consider is this a hand built pc or a prebuilt from dell etc? As it might have locked up drivers you have to use based on the system manufacturer vs the component manu.

Reality is none of them do shit sort of maybe plug any possible holes through the router. Almost all issues are caused by the user installing shit or visiting websites with a virgin client.

I use AVG because it's free and considered one of the best freeware solutions for viruses, spyware and malware. But, it's not perfect. Though, nothing is. As you said, spyware and malware is everywhere.

Suffice it to say, my computer is trying to update to build 1903. I currently have build 1803. I have tried 4 times to install the update by restarting and then restarting the installation, but every time I do, around 60% of the installation, it fails and says one or more components are not supported (or working I don't remember the exact wording).

My next step is to try and reach out to a Microsoft Technician to see if they can help me figure out which component is apparently preventing the installation of build 1903.

If they tell me that one of my components is outdated and needs to be replaced, I'm going to be furious. Because that means I have to spend money to install a Windows 10 update...

But regardless, for whatever reason, the roll back from trying to install 1903 back to 1803 has disabled my GTX 1660 Ti card. As such, my msinfo doesn't even read that there's a card installed, and the Device Manager has taken to "hiding" my display adapter. I need to figure out what's going on before November. Otherwise, I lose all security options from Windows. I do have the Avast Suite of programs on my computer, so not sure what this would result in, but, ultimately, I can't update Windows 10 until I figure out which hardware is causing problems.

Suggest asking that work friend to see what he can do. It sounds like something is bugged or not talking right. It could be some other component that has a loose connection or even a bad wire. I have had 3 sata wires go on me in the last year.

When I google things to do with the update or getting drivers going I am seeing a lot of people having to DL crap off the app store for MS and shit about DHC DCH DDC etc also loads of issues with cpu gpu combos. Again google to see if there is anything related to your exp IE win10 version what errors etc are shown and so forth.

Seeing too many results of various flavors of issues etc, some examples it just goes on and on.

https://community.spiceworks.com/topic/2217988-nvidia-graphics-issue-after-1903-update

https://www.theinquirer.net/inquirer/news/3078994/windows-10-may-update-surface-book-nvidia-gpu-issues

more I read more I suggest you roll back and or reinstall the os and not update this march 2019 update. It is bad when it is screwing up locked hdw configs on MS branded products.